In-house Tests & Quality Control

Newstar adopts 5S management in every process of manufacturing and passed ISO 9001 quality assurance system. We have system-

atic quality control and assessment system to ensure high quality of products before shipment.

All raw materials are thoroughly tested for a considerable time prior to being granted approval. From yarn weaving, PVC compounding,

PVC coating, ducting fabrication, the whole production process is under our strict control.

From the purchase of raw materials, the production of semi-finished products and finished products, our factory has a complete set of

data links, all products have barcodes, and each product has traceability.

Our fine quality control system has helped us win in the market and we believe our products will be accepted by more and more custo-

mers and end users from all over the world.

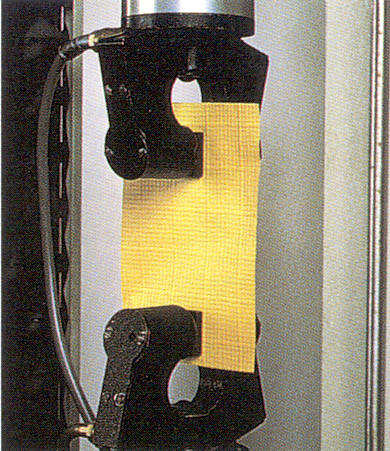

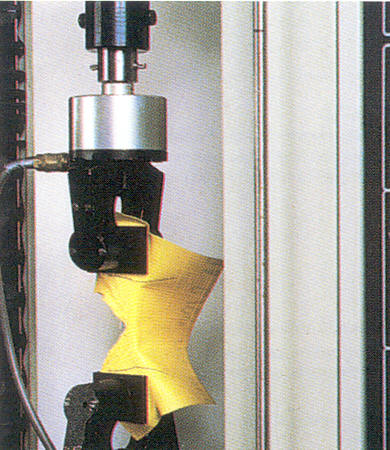

Tensile Strength

Based on DIN53354 Standard or ASTM Standard or ISO standard, sampling fabric would undergo a tensile test to meet end users’

requirements in the application. Superior tensile strength of ducting material can make the ducting work properly under very high air pressure.

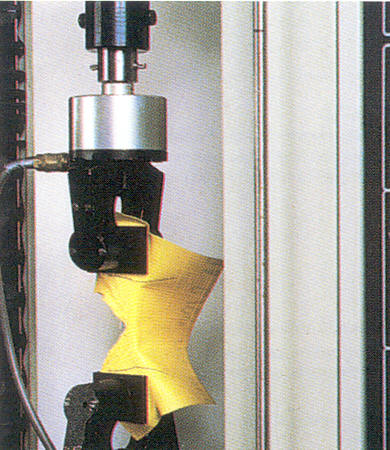

Tearing Strength

Based on DIN53363 Standard or ASTM Standard or ISO standard, sampling fabric would undergo a tearing test to judge whether it is qu-alified or not. Tearing strength is an important factor for the lifespan of ducting. With superior tearing strength, the small holes or scratches of ducting can not be enlarged in short time and the lifespan of ducting will be long.

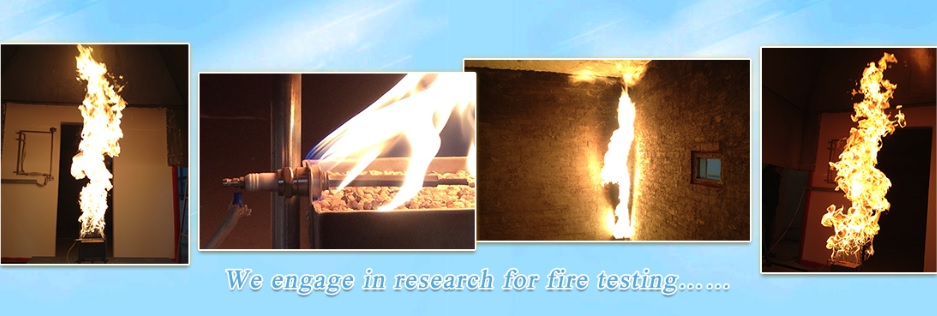

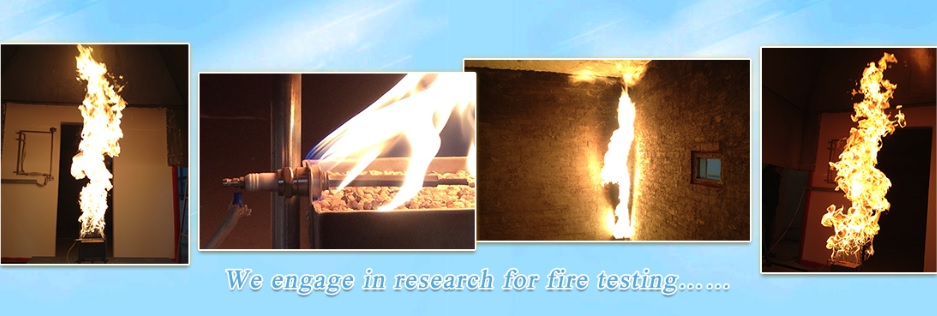

Flame Retardancy Test

For underground ventilation, the flame resistant property of ducting material is vital. The ducting must be self-extinguishing so that the workers can be safe even if there is fire in underground mining or tunnels.

For every batch of production, we perform the burning tests in the flame chamber to measure the flammability of a fabric when it is exposed to specific sources of ignition.

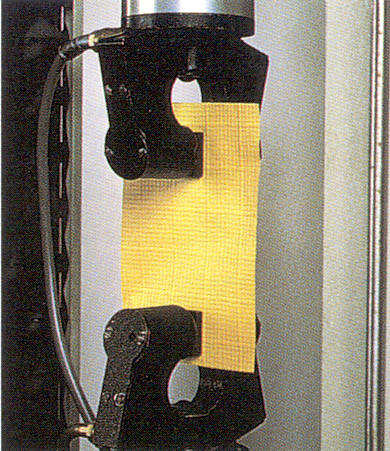

Anti-cold Test

Considering the ducting may be used in very chilly environment, the ducting material should be anti-cold to -40 Celsius degree.

According to the DIN, ASTM and ISO Standards, we put the sampling fabric in the low-temperature chamber and set the temperature

to 40 Celsius degree.

After 48 hours, we will evaluate the flexibility of the fabric to judge whether it is anti-cold or not.

Smoke Toxicity Test

All types of Newstar ducting material is eco-friendly and pro-environmental. Under burning, the smoke generated by our fabric are

proved NO harm to human body. We are the SOLE manufacturer of PVC ducting material in China who has SGS certification of smoke toxicity test.

After the ventilation ducts and fabric rolls are completed, the inspector will conduct random inspections on the appearance, hot welding seam, suspension seam, end coupling & tightness and other aspects. If every aspect meets our QC standards, the cargoes can be packed and stored in the warehouse and await delivery instructions. If not, we will check the quality one by one to guarantee for every piece of ducting is in high quality. We also can accept the third part inspection of goods before delivery.